Our latest investment in Sliding Head Technology, a Star SR-20JII Type B, with extra capacity to machine up to 22.22mm diameter stock bar. This was installed and set to work by Star GB Ltd in December 2023.

Published on Feb 6, 2024

Our latest investment in Sliding Head Technology, a Star SR-20JII Type B, with extra capacity to machine up to 22.22mm diameter stock bar. This was installed and set to work by Star GB Ltd in December 2023.

Published on Jan 28, 2022

Last year - July 2021, we joined a trade body called the British Turned parts and Machined Components Manufacturers Association (yes it’s a mouthfull!). So we are entitled to display their certificate on our web site. Please Click Here to download our certificate.

Published on Jan 28, 2022

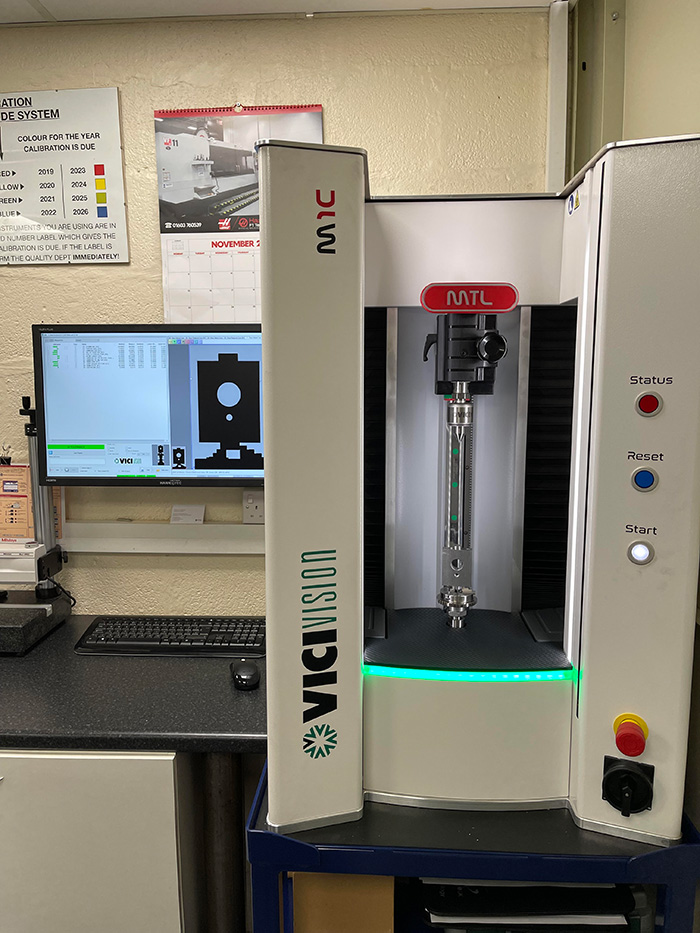

The Vicivision M1C is designed as the ideal measuring system for minute turned parts. The live image of the piece displayed by the metrology software, combined with the LED illuminated working area, gives a clear vision of the conditions of the component being measured.

The retractable sensors enabled during loading and unloading provide reinforcement, with additional one-of-a-kind protective bumpers.

An increased load capacity allows elements of up to 120mm in diameter to be positioned.

Published on Jul 1, 2021

The SR-32J is designed for complex large-diameter short workpiece machining, with a high rapid feed rate and power-driven sub-spindle tool greatly reducing processing time.

Published on Aug 1, 2020

Features a powerful milling drive and high speed, high accuracy C-Axis. The 3.22 in stroke Y-Axis ensures production of finished parts, and the elimination of secondary operations such as deburring, milling, drilling and re-positioning of fixtures.

Published on Nov 1, 2019

A smart, state-of-the-art software-controlled vending system to optimise inventory management.

Published on Sep 1, 2019

Ideal for small length-to-diameter ratio parts, The SR20-J supports a total of up to 30 cutting tools, including 14 power-driven tools for cross drilling, milling, slotting and angular hole machining. The 2-position deep drilling station allows drilled holes up to 10mm diameter by 100mm deep to be carried out on the main spindle.

The Fully independent sub spindle has a full C axis. Coupled with polar co-ordinates, it creates a virtual 'Y' axis, enabling the maxining of hexagon, square or other profiles.

Published on May 30, 2019

We have invested in another Sliding Head CNC machine from Star Micronics GB Ltd.

The SR-32JII Type B alllows us to machine complex parts up to 35mm diameter and provides extra capacity to meet our customers' demands. Also we can utilise the machine in either Guide Bush or Non-Guide Bush mode, reducing on material waste.

Thank you to Star GB for your ongoing support.

Published on Dec 12, 2018

In late 2017 we needed to increase our milling capacity, so we invested in a HAAS Super Mini Mill complete with a 4th axis capability. This was delivered and installed on February 7th 2018

In late 2017 we needed to increase our milling capacity, so we invested in a HAAS Super Mini Mill complete with a 4th axis capability. This was delivered and installed on February 7th 2018

Published on Sep 27, 2018

We were invited to Number 11 Downing Street to discuss

manufacturing and industry with then chancellor

Rt. Hon. George Osbone MP.